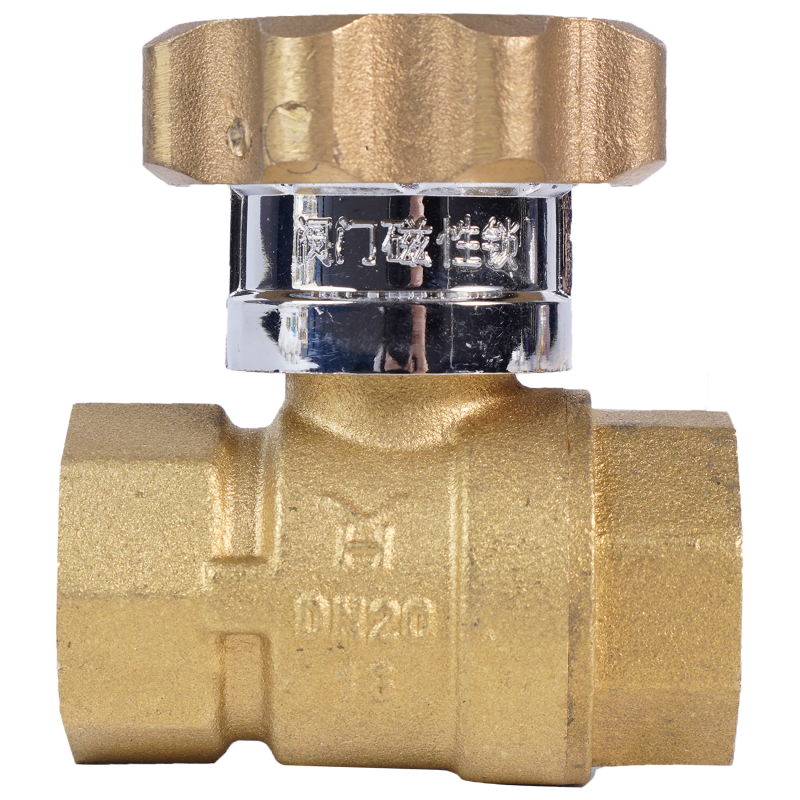

ball valve half inch manufacturer

A ball valve half inch manufacturer specializes in producing precision engineered flow control solutions for various industrial applications. These manufacturers employ advanced manufacturing processes and quality control measures to create reliable, compact valves that offer exceptional flow control capabilities. The production facilities typically feature state of the art machinery and testing equipment to ensure each valve meets strict industry standards. These manufacturers focus on creating ball valves that provide tight shutoff capabilities, minimal pressure drop, and excellent durability in demanding environments. The manufacturing process involves precision machining of valve bodies, careful selection of seal materials, and rigorous quality testing protocols. Modern ball valve manufacturers incorporate innovative design features such as anti static devices, fire safe construction, and specialized coating options to enhance valve performance and longevity. They often provide customization options to meet specific application requirements, including different end connection types, material selections, and operating pressure ratings. The production line typically includes automated testing facilities for leak detection, pressure testing, and functional verification of each valve before shipment. These manufacturers maintain strict quality control measures throughout the production process, from raw material inspection to final product testing.